Unmatched Precision and Custom Elastomer Bonding Solutions for Complex Applications

Specialized Elastomer Bonding for Critical Applications

Rubber-bonded components are essential for maximizing performance in numerous industries. We have extensive experience working on a variety of products that require precise elastomer bonding.

Vibration-isolating mounts for computer and production equipment.

Offset printing press rollers.

Overmolded spool valves.

Poppets, armatures, and plunger pins for pop-off valves.

Medical-grade platinum-cured silicone coatings for screens and seals.

Deep-hole oil drilling sensors.

Rubber-to-metal seals and rollers.

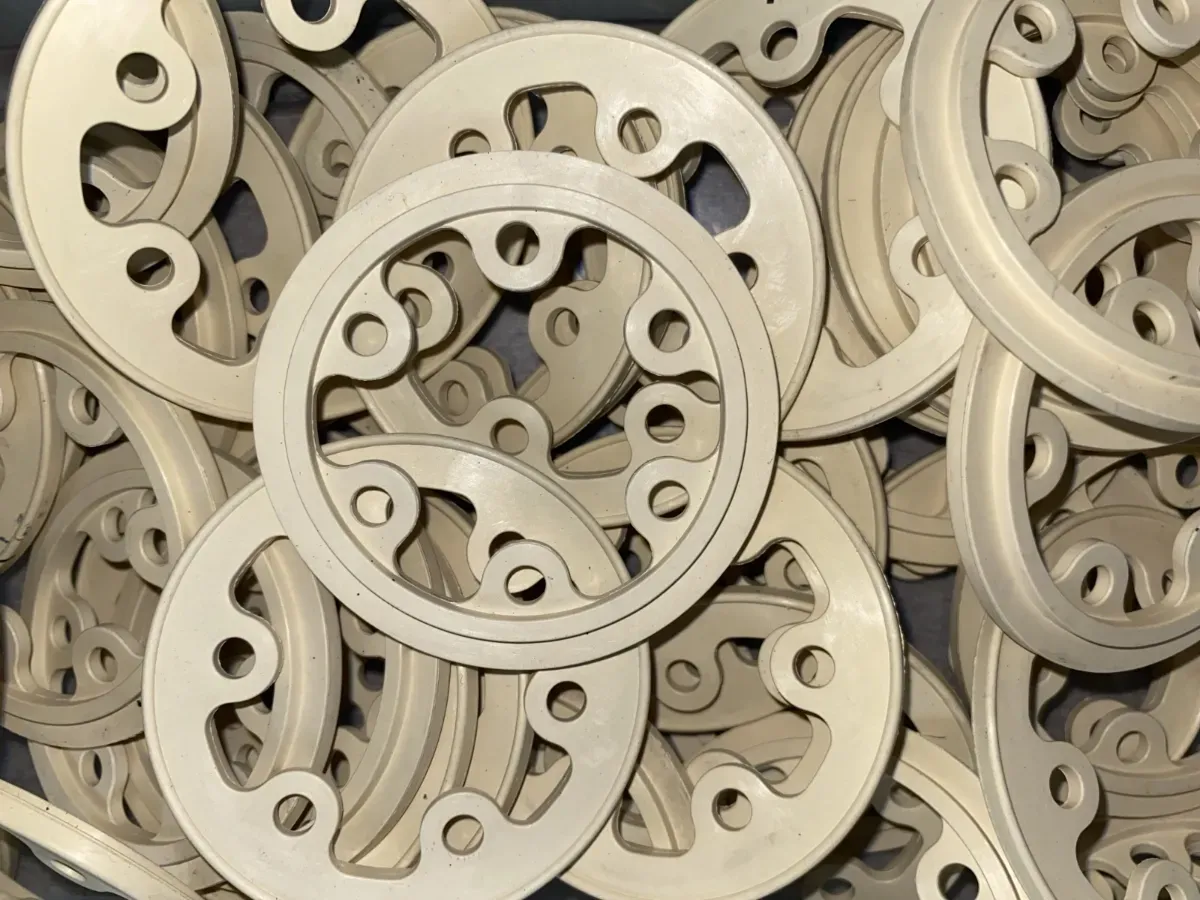

Rubber-bonded crash stops, actuators, stators, and magnetic latch assemblies for disk drives.

Each of these products is subject to thorough inspection and precision testing, including cleaning and deflashing at magnifications of 5X or greater. Our commitment to rigorous quality control ensures that every product meets exact specifications and performs reliably in its intended application.

High-Performance Solutions for Diverse Industries

From aerospace to medical devices, our custom elastomer solutions are designed to meet the toughest challenges and highest standards.

At High Tech Elastomers, we understand that every industry has unique demands. Our rubber-bonded components have been successfully applied in a wide range of sectors, providing durability, precision, and performance where it matters most. Whether you need components that withstand extreme temperatures, resist chemical exposure, or deliver unmatched precision, we have the expertise to deliver solutions tailored to your needs.

Substrates We Bond To

Stainless steel

Aluminum

Brass and bronze

Nylon

Glass

Plastic

Titanium

Super alloys

Space-age plastics

Other common metals and alloys

Super-smooth surfaces

Elastomers We Work With

Gum rubber compounds

Urethanes

Neoprenes

Silicones

NBR's and HNBR's

EPDM's

FfkM's

Butyl

fkM (VITON)

Our team of experts applies these advanced bonding methods to a wide range of substrates, achieving tolerances down to .0002 inches and surface finishes as fine as 8 RMS. Whether working with complex shapes or exotic materials, we guarantee superior bonding performance that enhances your product’s lifespan and functionality.

Decades of Expertise in Elastomer Bonding

High Tech Elastomers is renowned for its ability to bond elastomers to a variety of substrates with unmatched precision. Our bonding techniques are designed to improve performance, reduce wear, and ensure reliability in critical applications. We work with a wide range of elastomers and substrates to meet your unique project requirements.

This over molded stator is used for computer disk drives, and was produced by HTEI to meet very exact production and performance requirements

EXPERTS IN CREATING CUSTOM VALVE AND POPPET SEALING FOR OVER 50 YEARS!

High Tech Elastomers offers industry-leading elastomer bonding solutions with unmatched precision and quality. With ISO 9001-2015 certification and the ability to hold tolerances down to .0002 inches, we excel in creating custom elastomer formulations tailored to extreme environments. Our in-house mold design and prototyping services ensure faster turnarounds and cost-effective solutions for even the most complex applications, making us a trusted partner across industries such as aerospace, automotive, and medical devices.

Tailored Compounds for Your Unique Needs

Achieve optimal performance with custom elastomer formulations that meet your specific application requirements.

Our team specializes in developing elastomer compounds designed to tackle the most challenging applications. Whether you're working with exotic metals, smooth composites, or specialized plastics, we create bonds that are durable and reliable. Our formulations are engineered to withstand high pressure, extreme temperatures, and prolonged exposure to oils, chemicals, and abrasion—ensuring long-lasting performance in demanding environments.

ISO 9001-2015 Certification for Precision and Quality

Honing our processes under strict ISO 9001-2015 guidelines, we maintain world-class quality control. This certification ensures every rubber-bonded component we produce meets international quality and safety standards, giving clients peace of mind.

Ultra-Precise Tolerances and Surface Finishes

We are capable of holding tolerances down to .0002 inches and surface finishes to 8 RMS. Our advanced equipment ensures consistency and precision even in highly complex or critical applications, such as in the aerospace and medical device sectors.

Custom-Formulated Elastomers for Specialized Applications

We specialize in developing custom elastomer formulations for extreme environments, including high-temperature and pressure applications, chemical-resistant compounds, and materials that endure continuous friction. From oil & gas exploration to high-performance medical devices, we create elastomers that meet the exact specifications required.

Prototyping and Low-Volume Production with Full-Scale Capabilities

Our prototyping services allow clients to test and validate rubber-bonded components before moving to full-scale production. We handle everything from small-batch prototypes to large, multi-year production runs, ensuring seamless scalability for any project.

Experience Across Diverse Industries

With decades of experience in industries like aerospace, automotive, and medical devices, our expertise spans a wide range of elastomer bonding technologies. We have successfully worked with exotic metals, space-age plastics, and super-smooth substrates, providing robust solutions for even the most demanding applications.