Precision Elastomer to Substrate Bonding Solutions for Global Industries

Delivering ISO-Certified, High-Performance Elastomers and Elastomer to Substrate Bonding for Aerospace, Automotive, Medical, and Industrial Applications Worldwide.

High Tech Elastomers is ready to bond your choice of compound to your choice of substrate

High Tech Elastomers delivers all the rubber-bonding technology your product application requires

For the best bonding precision and quality, plus responsive service, rely on your partners at High Tech Elastomers

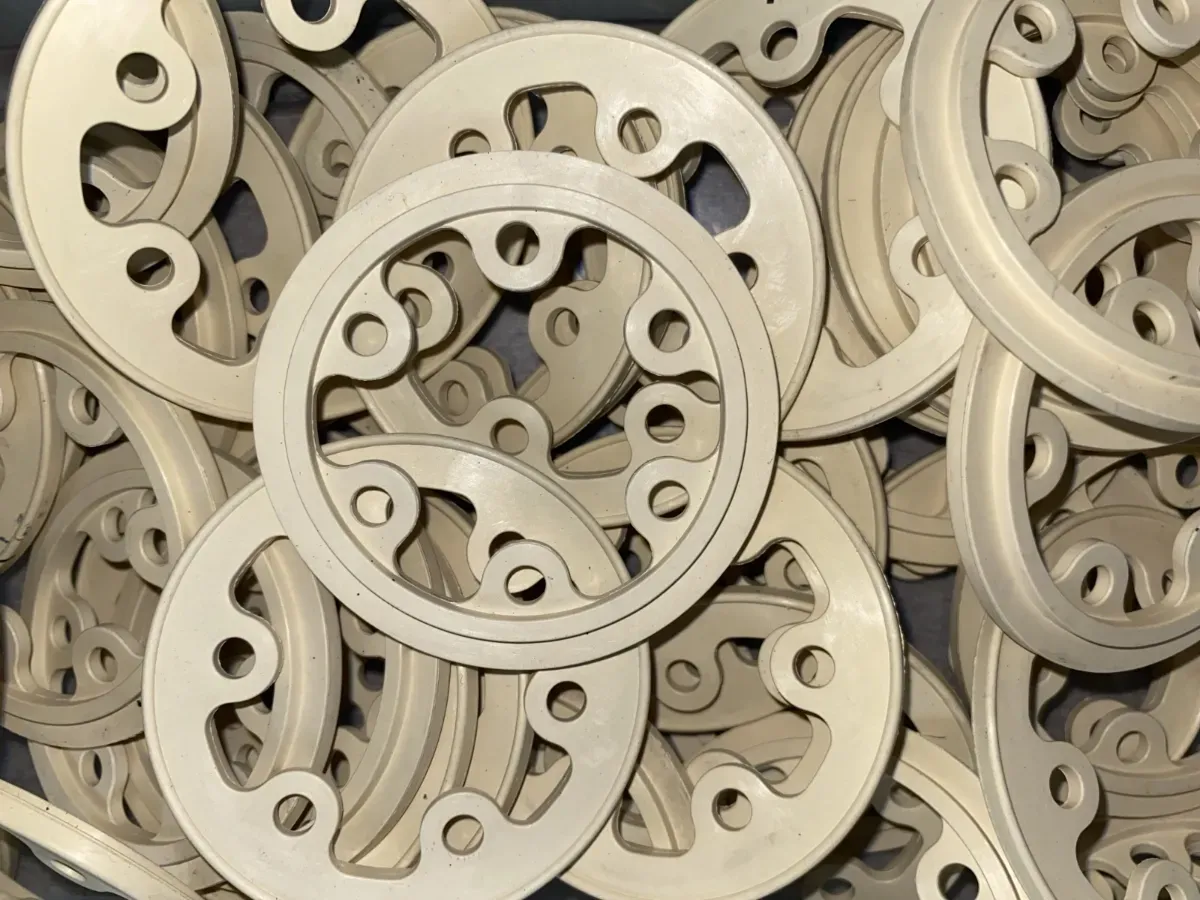

EXPERTS IN CREATING CUSTOM VALVE AND POPPET SEALING FOR OVER 50 YEARS

We specialize in delivering elastomer bonding solutions for a wide variety of industries around the globe. Our cutting-edge bonding technology guarantees exceptional precision, durability, and performance in sectors where top-quality rubber-to-substrate components are essential.

Aerospace

High-performance elastomer seals, vibration isolators, and rubber-bonded components designed to meet the stringent demands of aerospace systems.

Industrial Machinery

Durable elastomer components for heavy-duty industrial equipment, including rubber-bonded rollers, seals, and vibration dampeners.

Oil & Gas

Specialized elastomer-bonded components for deep-well drilling sensors and harsh environmental conditions, providing durability and resistance to chemicals and extreme temperatures.

Medical Devices

Medical-grade elastomer coatings and bonded components, such as silicone-coated seals and screens, designed for use in precision medical equipment.

Semiconductor

Precision-bonded elastomer seals and components used in the semiconductor industry to ensure reliable performance in high-tech applications.

Automotive

Custom elastomer-to-metal bonding solutions for automotive parts, including seals, mounts, and components built to withstand extreme temperatures and pressures.

Backed by years of experience, we are dedicated to providing world-class elastomer bonding solutions that set new industry standards for precision, quality, and innovation. Our mission is to collaborate with global industries, offering custom elastomer formulations and bonding methods tailored to meet the unique demands of every project. From initial consultation through final production, our focus remains on delivering results that exceed expectations and provide lasting performance across a wide range of applications.

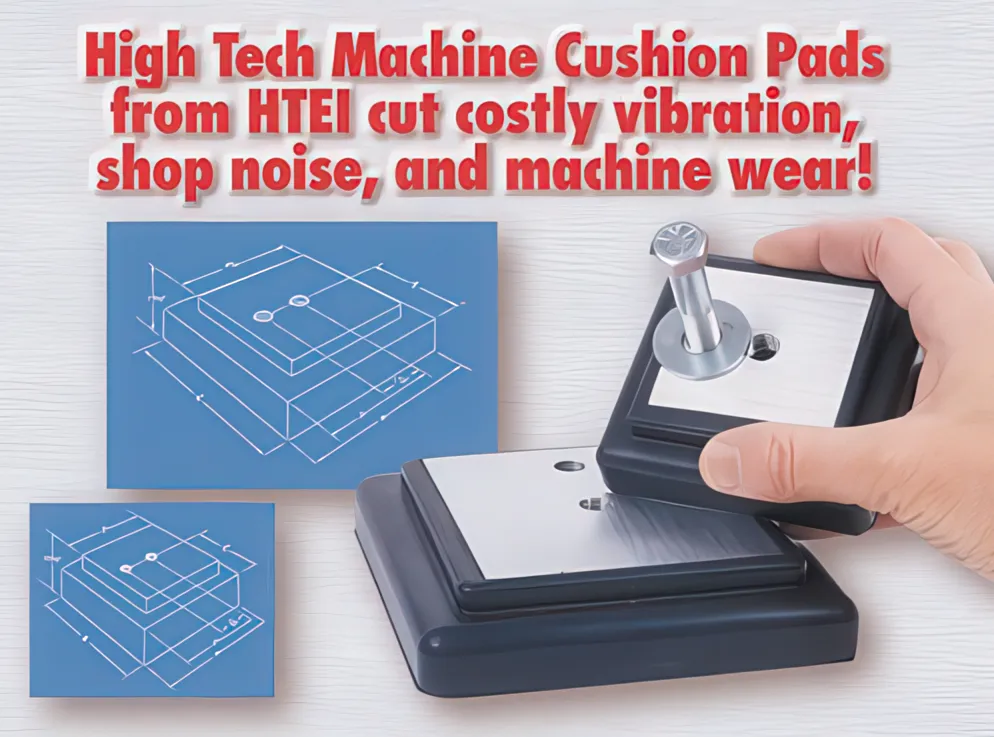

Our machine cushion pads, available in standard sizes, are designed to reduce vibration, noise, and wear, helping to extend the life of your machinery. Plus, they are quick and easy to install, minimizing downtime and keeping your operations running smoothly.

Looking for seals and gaskets tailored to your equipment? Discover our full range of custom-molded seals made from high-performance elastomeric materials, from Nitrile to FFKM.

No matter your industry, High Tech Elastomers has the expertise to deliver high-performance elastomer bonding solutions tailored to your needs. Contact us today to discuss your project requirements.

Elastomer Bonding Services Tailored to Your Industry

At High Tech Elastomers, we offer a range of elastomer bonding services designed to meet the unique needs of diverse industries. From custom formulations to precision bonding, our services are crafted for paramount performance in challenging environments.

Advanced Rubber-to-Metal Bonding

Achieve durable, high-performance bonding solutions specifically designed for complex shapes and challenging materials. Whether working with stainless steel, aluminum, super alloys, or other exotic metals, our advanced bonding techniques ensure a strong, reliable bond that stands up to demanding applications. Our process is engineered to meet the highest industry standards, delivering superior performance, long-lasting durability, and resistance to extreme conditions. From aerospace to automotive and industrial sectors, we provide the expertise and technology to create customized bonding solutions that match your exact specifications and withstand the toughest environments.

Tailored Elastomer Formulations

Develop custom elastomer compounds specifically engineered to meet the unique demands of your environment. Whether it’s resistance to extreme temperatures, chemicals, abrasion, or wear, we craft formulations that deliver top performance and durability. Our compounds are designed to address specific industry challenges, ensuring longevity and reliability even in the harshest conditions. From initial concept to final production, we work closely with you to ensure every formulation meets your exact specifications.

Medical-Grade Rubber-to-Metal Bonding

Our medical-grade elastomer coatings and bonding solutions are expertly crafted for precision, safety, and reliability in healthcare applications. Designed to meet the stringent standards of the medical industry, our advanced bonding processes ensure compatibility with a wide range of medical devices and equipment. Whether for diagnostic tools, surgical instruments, or patient care devices, our elastomer bonding solutions deliver exceptional performance and durability in critical environments. With a focus on biocompatibility and hygiene, we provide customized solutions that help ensure the highest level of safety and reliability for healthcare professionals and patients alike.

Prototype and Small-Batch Production

Test, refine, and validate your products with precision-engineered prototypes designed to ensure optimal bonding performance, material compatibility, and quality control before full-scale production. These prototypes allow for thorough evaluation under real-world conditions, minimizing risks and addressing potential challenges early in the development process. Tailored for efficiency, this approach not only streamlines production but also reduces costs associated with large-scale manufacturing errors. By ensuring each prototype meets the highest standards, we help safeguard the success of your final product.

ISO-Certified Manufacturing

Scale your production seamlessly with our ISO-certified manufacturing process, designed to ensure consistent quality and precision at every stage. Whether you're ramping up for high-volume output or transitioning from prototypes to full-scale production, our processes are engineered to meet the highest global standards. With a focus on efficiency, we guarantee meticulous attention to detail throughout, reducing waste and optimizing performance. Our certification reflects our commitment to maintaining the strictest quality controls, giving you confidence that every product meets your exact specifications, no matter the scale of production.

Ready to enhance your products with precision elastomer bonding? Contact us today to learn more about our custom solutions and how we can meet your unique industry needs.

ATTENTION: Design & Production Teams

We're ready to partner with your design and production team on any challenge you face

Looking for innovative elastomer bonding solutions? High Tech Elastomers is your trusted partner for precise, cost-effective rubber-to-substrate bonding. Whether you're developing prototypes or managing large-scale production, our team can help solve your toughest challenges—from extreme temperatures to hazardous environments. Join industries worldwide that rely on our expertise to ensure quality, precision, and performance for every project.

Partner with us Today

Let’s collaborate to drive your success, reduce your costs, and bring your designs to life with the highest standards of quality and performance.

Machine Cushion Pads for Superior Performance

For all the motorized machinery and heavy equipment in your plant, laboratory, or shop, it pays to invest in High Tech Machine Cushion Pads

Reduce vibration, minimize wear, and extend the life of your equipment with our precision-engineered machine cushion pads. Designed to withstand heavy loads and extreme conditions, our pads provide durable, reliable protection for all types of industrial machinery. Whether you need custom sizes or specialized materials, we have the expertise to deliver the perfect solution for your needs.

Experience enhanced machine efficiency today.

Contact us now to request a quote or learn more about our custom machine cushion pads.

Precision Solutions, Proven Expertise.

High Tech Elastomers Inc. is a leader in the development of rubber-bonded parts, known for precision and quality. As an ISO 9001-2015 Certified Company, we pride ourselves on delivering world-class products and services.

High Tech Elastomers Inc. (HTEI) is a trusted global leader in elastomer-to-substrate bonding, known for solving the toughest challenges in industries such as aerospace, automotive, medical devices, and industrial machinery. We specialize in creating custom elastomer formulations and developing precise bonding methods that ensure superior performance and durability. Whether you're looking for prototype development, small-batch production, or large-scale manufacturing, our advanced capabilities ensure that every component meets your exact specifications.

As an ISO 9001-2015 certified company, HTEI upholds world-class quality standards in every project. Our expertise in bonding to a diverse range of substrates—including stainless steel, titanium, glass, and space-age plastics—enables us to tackle even the most complex elastomer bonding requirements. With tolerances held to .0002 inches and surface finishes to 8 RMS, we deliver components that exceed industry standards, ensuring precision, reliability, and repeatable performance across all applications.

At HTEI, we build long-term partnerships by providing tailored elastomer bonding solutions that save time, reduce costs, and enhance product performance. From initial consultation through to production, we collaborate with our clients at every step, offering in-house mold design, prototyping, and custom formulations. Our commitment to innovation, quality, and customer satisfaction has earned us a reputation for excellence in elastomer bonding technology.

This specialized bubble-test fixture was provided by our customer to facilitate the performance testing of precision seals produced for the semiconductor industry.

Many inspection procedures at High Tech Elastomers call for high degrees of magnification to assure proper bonding and accurate dimensions

Thorough inspection, cleaning and deflashing of these bonded components is all done at magnifications of 5X or greater by our trained technicians. Each part produced by High Tech Elastomers passes through this and numerous other procedures to assure the precise quality and reliable performance of your rubber-bonded components.

This medical grade mill assures that our specialized compound formulations are thoroughly and precisely mixed prior to molding.

Experience the High Tech Elastomers difference—precision, quality, and innovation you can count on. Contact us today to learn how we can help your business succeed.

Frequently Asked Questions

Q:

What industries does High Tech Elastomers serve?

High Tech Elastomers provides elastomer bonding solutions for a wide range of industries, including aerospace, automotive, medical devices, industrial machinery, and oil & gas. Our expertise allows us to tackle the unique bonding challenges presented by each sector.

Q:

What are your capabilities in precision bonding?

We specialize in precision elastomer bonding with tolerances as tight as .0002 inches and surface finishes up to 8 RMS. Our advanced equipment and expertise ensure consistent accuracy and reliable performance, even for complex or high-stakes applications.

Q:

What is elastomer-to-substrate bonding?

Elastomer-to-substrate bonding refers to the process of securely attaching elastomer materials to other substrates, such as metals, plastics, glass, and alloys. This process enhances the performance and durability of components used in critical applications across various industries.

Q:

Can you create custom elastomer formulations?

Yes, we can custom formulate elastomer compounds to meet the specific requirements of your project. Whether you need materials that withstand extreme temperatures, chemical exposure, or continuous friction, our team will develop a solution that meets your needs.

Q:

What types of substrates can you bond elastomers to?

We have extensive experience bonding elastomers to a variety of substrates, including stainless steel, titanium, aluminum, nylon, glass, super alloys, and other smooth or exotic materials. This versatility allows us to serve industries with highly specialized bonding needs.

Q:

Are you ISO 9001-2015 certified?

Yes, High Tech Elastomers is ISO 9001-2015 certified, meaning we follow stringent quality management standards to ensure the highest level of quality in every product we produce. Our certification reflects our commitment to excellence in both processes and outcomes.

Phone

Hours

Monday - Friday, 8:00 am - 5:00 pm

Privacy Policy | Terms of Service

© 2025 High Tech Elastomers Inc., All Rights Reserved | Site created by Webnine LLC