Durable Support for Heavy Machinery

Protect Your Equipment with High-Tech Cushion Pads

Designed for durability and performance, our machine cushion pads support even the heaviest machinery with ease.

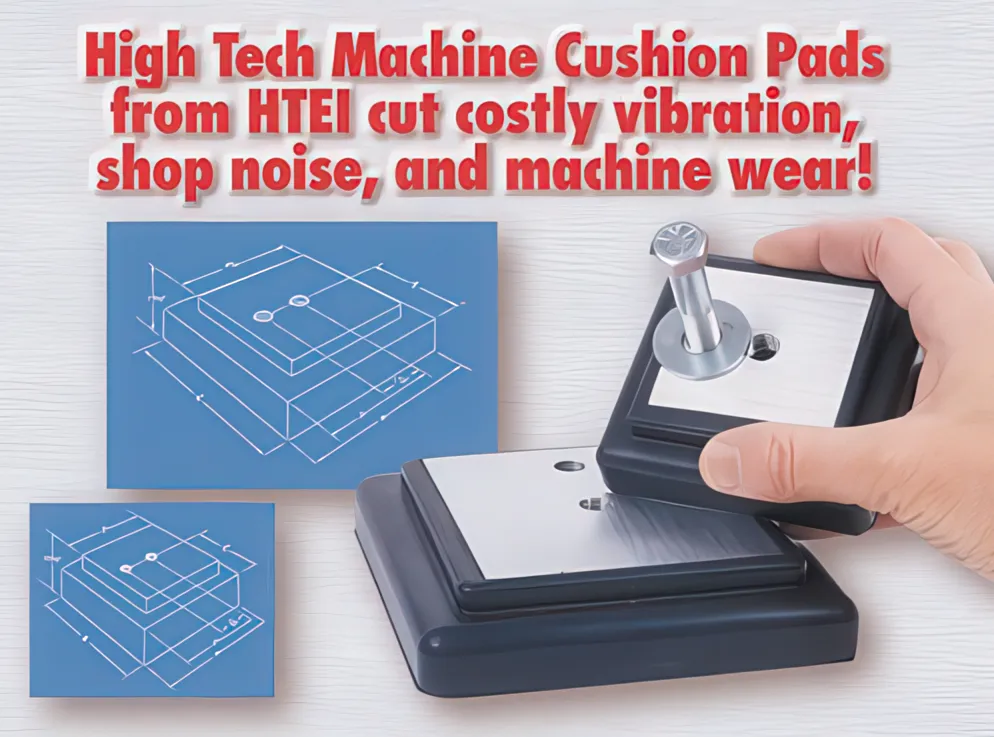

High Tech Machine Cushion Pads are available in either 4x4-inch or 6x6-inch sizes, with a choice of two elastomer compounds—offering either 60- or 80- durometer hardness. The higher compound hardness is ideal for supporting heavier machines. Each pad features a high-strength aluminum alloy mounting plate, permanently embedded into the mount's tough elastomer base for lasting strength and stability.

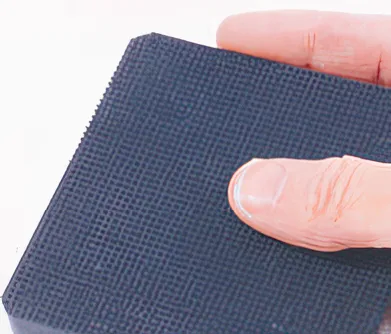

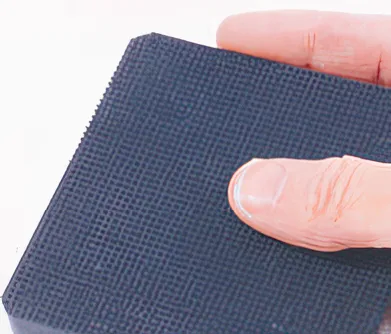

Thousands of tiny suction pockets on the bottom of the High Tech Machine Cushion Pad help keep machines from walking or slipping out of position

Vibration Control for a Smoother Operation

Say Goodbye to Harmful Vibration

Extend the lifespan of your machines while reducing building maintenance costs with our innovative cushion pads.

High Tech Machine Cushion Pads are the ideal solution for reducing disruptive vibration and noise in heavy machinery, compressors, and presses. They effectively isolate test equipment and CMMs, ensuring accurate results while minimizing wear and tear on your devices. By attenuating vibrations before they reach the floor or building structure, you’ll save on costly repairs and keep your machinery running smoothly.

Vibration Control for a Smoother Operation

Say Goodbye to Harmful Vibration

Extend the lifespan of your machines while reducing building maintenance costs with our innovative cushion pads.

High Tech Machine Cushion Pads are the ideal solution for reducing disruptive vibration and noise in heavy machinery, compressors, and presses. They effectively isolate test equipment and CMMs, ensuring accurate results while minimizing wear and tear on your devices. By attenuating vibrations before they reach the floor or building structure, you’ll save on costly repairs and keep your machinery running smoothly.

Thousands of tiny suction pockets on the bottom of the High Tech Machine Cushion Pad help keep machines from walking or slipping out of position

Try and Experience the Difference

See the Impact of Reduced Vibration

Experience improved performance, reduced noise, and extended equipment life with High Tech Machine Cushion Pads.

Discover the advantages of High Tech Machine Cushion Pads firsthand. With their durable design, effective vibration reduction, and easy installation, these pads are an essential upgrade for any facility with heavy machinery or precision equipment. See how our cushion pads can reduce noise, minimize machine wear, and improve the overall efficiency of your operations.

Pads can be levelled and aligned in minutes without special tools. Each mount includes a cold forged 1/2" bolt in a standard 2 1/2" length

Try one set of High Tech Machine Cushion Pads and experience the difference in noise and vibration reduction.

The elastomer compound used in High Tech Machine Cushion Pads is highly resistant to oil and chemicals, which assures many years of performance, even in tough operating conditions.

Easy Installation and Flexibility

Fast Setup, Easy Relocation

Install, adjust, and relocate your equipment effortlessly with High Tech Machine Cushion Pads.

With two tapped bolt holes in each aluminum mounting plate, our cushion pads offer flexibility when attaching and leveling your machinery. High Tech Machine Cushion Pads do not fasten to or damage your floor, making relocation quick and simple. Once installed, you can easily level and realign your equipment, saving you time and effort during maintenance or adjustments. Try a set of High Tech Machine Cushion Pads today and experience the difference in vibration control and machine stability.

Easy Installation and Flexibility

Fast Setup, Easy Relocation

Install, adjust, and relocate your equipment effortlessly with High Tech Machine Cushion Pads.

With two tapped bolt holes in each aluminum mounting plate, our cushion pads offer flexibility when attaching and leveling your machinery. High Tech Machine Cushion Pads do not fasten to or damage your floor, making relocation quick and simple. Once installed, you can easily level and realign your equipment, saving you time and effort during maintenance or adjustments. Try a set of High Tech Machine Cushion Pads today and experience the difference in vibration control and machine stability.

The elastomer compound used in High Tech Machine Cushion Pads is highly resistant to oil and chemicals, which assures many years of performance, even in tough operating conditions.

Built for Strength and Flexibility

Engineered for Stability and Precision

Durable aluminum alloy plates and flexible mounting options ensure your machinery stays balanced and secure during operation.

Every High Tech Machine Cushion Pad features a high-strength aluminum alloy mounting plate, permanently embedded within a robust elastomer base. The embedded plate provides superior durability, ensuring that your machinery remains stable and secure. Additionally, two tapped bolt holes in each mounting plate offer greater flexibility when it comes to attaching and leveling your equipment. This design allows for precise adjustments, keeping your machinery perfectly balanced during operation.

For vibrating polishers, these sturdy mounts isolate much of the shock from each vibrating cycle to extend the life of the floor, and also reduce machine "chatter" and "walking".

Secure, stable, and easy to adjust—our cushion pads keep your equipment perfectly aligned.

The Ultimate Solution for Vibration Control and Durability

Boost Machine Longevity and Performance with High Tech Cushion Pads

Engineered for superior vibration control, easy installation, and unmatched durability—protect your investment with cushion pads that deliver lasting results.

High Tech Machine Cushion Pads are your go-to solution for stabilizing and protecting heavy machinery, compressors, and precision equipment. Available in 4x4-inch or 6x6-inch sizes with options of 60- or 80- durometer hardness, these pads provide unmatched support for even the most demanding applications. Designed with a high-strength aluminum alloy mounting plate, each pad is permanently embedded in a tough elastomer base, ensuring strength and stability you can rely on.

Say goodbye to disruptive vibrations that shorten the lifespan of your equipment and increase building maintenance costs. Our cushion pads are engineered to isolate vibrations, reducing noise and protecting sensitive test equipment like CMMs from unwanted interference. Not only do they prevent damage to your floor, but they also make it easy to relocate and adjust your machinery whenever needed—ensuring flexibility and convenience in your operations.

Choose High Tech Machine Cushion Pads and experience the difference they can make in reducing vibration, extending equipment life, and maintaining a quieter, more efficient workspace.

Phone

Hours

Monday - Friday, 8:00 am - 5:00 pm

Privacy Policy | Terms of Service

© 2025 High Tech Elastomers Inc., All Rights Reserved | Site created by Webnine LLC

Frequently Asked Questions

Q:

What industries does High Tech Elastomers serve?

High Tech Elastomers provides elastomer bonding solutions for a wide range of industries, including aerospace, automotive, medical devices, industrial machinery, and oil & gas. Our expertise allows us to tackle the unique bonding challenges presented by each sector.

Q:

What are your capabilities in precision bonding?

We specialize in precision elastomer bonding with tolerances as tight as .0002 inches and surface finishes up to 8 RMS. Our advanced equipment and expertise ensure consistent accuracy and reliable performance, even for complex or high-stakes applications.

Q:

What is elastomer-to-substrate bonding?

Elastomer-to-substrate bonding refers to the process of securely attaching elastomer materials to other substrates, such as metals, plastics, glass, and alloys. This process enhances the performance and durability of components used in critical applications across various industries.

Q:

Can you create custom elastomer formulations?

Yes, we can custom formulate elastomer compounds to meet the specific requirements of your project. Whether you need materials that withstand extreme temperatures, chemical exposure, or continuous friction, our team will develop a solution that meets your needs.

Q:

What types of substrates can you bond elastomers to?

We have extensive experience bonding elastomers to a variety of substrates, including stainless steel, titanium, aluminum, nylon, glass, super alloys, and other smooth or exotic materials. This versatility allows us to serve industries with highly specialized bonding needs.

Q:

Are you ISO 9001-2015 certified?

Yes, High Tech Elastomers is ISO 9001-2015 certified, meaning we follow stringent quality management standards to ensure the highest level of quality in every product we produce. Our certification reflects our commitment to excellence in both processes and outcomes.